The In the intricate system of a boiler plant, the Air Preheater (APH) plays a pivotal role in heat recovery. The hot gas in the APH duct can cause vibrations that can damage the system's structure. This study looks at how baffles affect vibrations from fluid flow in the APH duct and system stability.

A crucial aspect of boiler plants involves the circulation of hot flue gas to optimize heat exchange. The Air Preheater (APH) facilitates this process by preheating the combustion air using the waste heat from the flue gas. The strong flue gas causes vibrations in the duct, known as Flow-Induced Vibrations (FIV). Understanding and mitigating these vibrations are essential for maintaining the long-term reliability of the system.

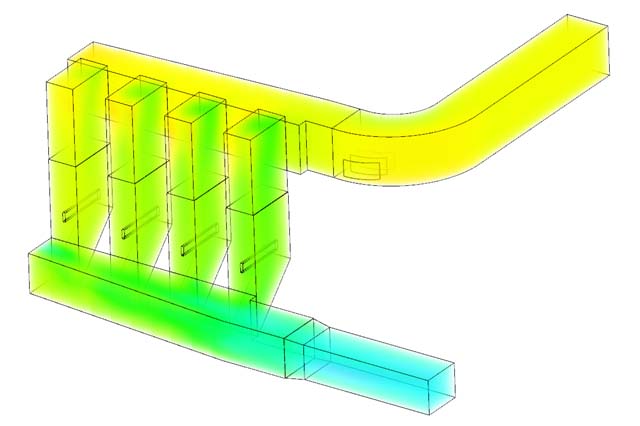

CFD Analysis of Duct Flow:

Computational Fluid Dynamics (CFD) analysis provides valuable insights into the dynamics of duct flow. The simulation examines how gas moves in the Air Preheater (APH) duct and studies pressure, flow separation, and vortex formations.

The accuracy of these estimates depends on the mesh resolution. The mesh resolution needs to be able to resolve the boundary layer. Flow interactions happen in the boundary layer.

Importance of Baffles in FIV Analysis:

The simulation examines how baffles aid in reducing flow changes in the Air Preheater (APH) duct during FIV analyzing. Baffles act as strategic components that influence the flow dynamics, particularly reducing bend losses and pressure fluctuations. This reduction in flow fluctuations contributes to an overall stabilization of the system. The analyzing looks at how baffles affect pressure drop, giving a complete understanding of their impact.

Duct Flow Simulation with Baffles:

The simulation scenario explains how baffles in the Air Preheater (APH) duct affect the flow dynamics. Baffles control flow patterns to reduce the negative impact of flow frequencies aligning with structural frequencies. The simulation evaluates how baffles effectively reduce flow-induced vibrations, contributing to enhanced system stability.

Evaluation Parameters in FIV Analysis:

We assess the results of the FIV analysis based on key parameters such as velocity pressure and frequency variation. These parameters offer quantitative insights into the impact of baffles on flow stability. The analyzing looks at how baffles affect the flow of the Air Preheater (APH) duct, showing how they impact its performance.

Benefits of Baffles in Air Preheater Duct:

The FIV analysis reveals that the incorporation of baffles in the Air Preheater (APH) duct significantly reduces flow fluctuations. This reduction means less bending losses and pressure changes, leading to better system stability. The advantages include reducing vibrations, improving energy efficiency, and increasing the lifespan of the APH and its parts.

Real-World Applications:

The findings from the FIV analysis hold practical implications for boiler plants and similar industrial settings. Use optimized design with baffles to stabilize APH ducts and ensure reliable and continuous operation. Industries reliant on efficient heat recovery systems can benefit from these insights, experiencing reduced maintenance costs and increased operational efficiency.

Challenges and Considerations:

While the FIV analysis offers valuable insights, challenges persist in accurately simulating real-world conditions. We need to check the simulation with real data and study how different conditions affect it. Additionally, the structural characteristics of baffles, such as their shape and material, may influence their effectiveness in vibration reduction.

Conclusion:

Studying FIV of the Air Preheater (APH) duct helps us learn about flow vibrations and how baffles can lessen them. The simulation highlights the significance of baffles in reducing flow fluctuations, bend losses, and pressure variations, ultimately contributing to enhanced system stability.

The findings help industries enhance Air Preheater (APH) system performance and minimize issues with FIV in high-pressure ducts. This case study assists industries in enhancing the design and operation of APH ducts. As a result, it leads to the development of more stable systems that are both efficient and reliable.